I

Some time in the past decade, we discovered there was a whole universe of possibilities right above our heads, and the private space race began anew. Like with many things, we can thank Elon Musk. After all, he did go try to build a Russian rocket, get shot down and then decide to build his own, burn his money on three failed launches (and I'm sure countless engineers), and build an entire launch programme fresh with reusable rockets. And discovered Twitter.

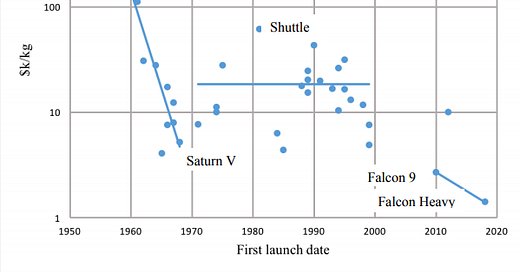

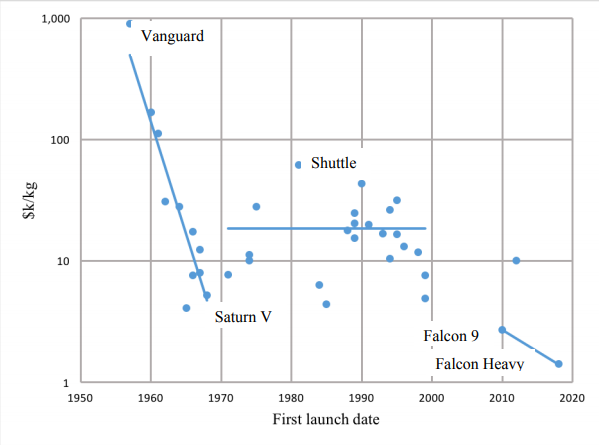

If you believed in the Great Stagnation, wouldn't this make you want to throw out that thesis? If you need even more information to help make up your mind, here's some data. It's from a paper by Harry W Jones.

NASA’s space shuttle had a cost of about $1.5 billion to launch 27,500 kg to Low Earth Orbit (LEO), $54,500/kg. SpaceX’s Falcon 9 now advertises a cost of $62 million to launch 22,800 kg to LEO, $2,720/kg.

Sure looks like the Stagnation has come to an end. But it sure took a while. The general narrative of space exploration cites SpaceX, rightly, as creating an incredible impetus for the rest of the industry to play catch up and up its game. And it's true. When you look at the history of private spaceflight, there just isn't much to report in the 80s or 90s, or even in the 2000s. An article on the commercial spaceflight industry says approvingly:

Capitalism finally infiltrated spaceflight in the 2010s, and that meant competition was in full swing.

So why did it take a few decades of Stagnation to get here? Why do we have headlines like Why NASA is stagnant? Were we just complacent in our capabilities and just chilled for a while after getting someone on the moon?

The paper also describes the reasons for the decline in launch costs.

Reusable rockets

This was Elon Musk's great idea. But it's complicated by the fact that creating a reusable rocket has higher developmental costs and increased fuel needs, which makes it, net-net, not as much of a slam dunk as it sounds. The projected cost savings of Falcon 9 are still in the future.

Better, streamlined, commercial production

As with most things, if we're not making products bespoke, in highly controlled and fault-tolerant systems, then you're going to have high cost. The way we solved that in literally every other industry was better standardisation and reducing complexity, and the same thing should apply here. But this is a "let's rethink how we design rockets in the first place" answer, which isn't particularly easy.

From Wikipedia on the history of SpaceX

By applying vertical integration—principally for cost reasons; around 85% of the entire Falcon/Dragon vehicle is produced in-house— and the modular approach from software engineering (...), SpaceX could cut launch price by a factor of ten and still enjoy a 70 percent gross margin

Most interestingly, these aren't new principles. There's no real reason they weren't used in existing manufacturing processes beyond inertia.

Better management

Needless to say, this is a popular sentiment for those favouring private enterprises. NASA estimated what the cost would've been if they'd tried to develop Falcon 9 and came up with a figure that was 68% higher than what SpaceX had spent.

Which makes sense. SpaceX is tasked with doing one thing, and they do it well, like extremely talented fanatics. They insource most things, have very few management layers and iterate quickly. It makes sense that they're able to build cheaper rockets.

Better Design

Space X made several iterations to test out optimal structures, and this resulted in actual savings in the rocket's design and assembly. It's mentioned over and over that their core idea to reduce costs and increase resilience is simplicity. This means all their rockets are designed the same regardless of payload or destination.

Also, there is a large amount of iteration and specific design thinking that goes into each aspect of the rocket, making it cheaper. For instance:

Earlier versions of the rocket had nine engines arranged in three rows of three. With the Octaweb, eight engines are clustered in a circle around a central one. The different engine ... reduces the length and weight of the Falcon 9 thrust structure, simplifying the rocket’s design and assembly.

While the majority of rockets use a complicated pyrotechnic system of explosive bolts to separate stages, SpaceX uses an all-pneumatic stage separation system.

In the end, this quote sums it up.

The commercial competitive launch approach sponsored by NASA provided an unconstrained environment that allowed a focused management to cut costs using good engineering. Competition drives innovation and forces efficiency, cuts costs and creates new opportunities.

II

But this still doesn't explain why it took us fifty years since the moon landing to have a functioning Space X. So was it that this was just inordinately hard, or that we didn't care? Was it ineptitude or apathy?

This is just really hard

We shouldn't expect to be able to do hard things regularly, because they're hard. While of course it's possible, this argument only works in a vacuum. Because while we've stagnated in our search for doing the harder things in space, we've succeeded in doing the hard things in plenty of other industries.

We sequenced the whole genome, for instance. That was pretty cool. We have nanomaterials, which seemed like science fiction in the past (and still does). We have quantum computers that do wacky things, and though that doesn't seem like much it's still pretty incredible. We can dream of creating vaccines in a matter of months against whole sequences of diseases.

So if the argument is that better engineering and better management were the keys to making this happen, there's no reason that couldn't have been done decades ago.

We didn't care to do it

If it wasn't that it was objectively hard, it was that we didn't subjectively care to do it.

But what this misses is that we did a fair bit with space still. Geosynchronous satellites, popularised by Arthur C Clarke, helped bring about a minor communications revolution. Starting with Syncom3, there's been plenty of entrants. EchoStar, Lockheed Martin, WildBlue, all threw their hats in the ring in the 90s. Even Microsoft burned $9Bn through trying out Teledesic, similar to what Space X is doing today with Starlink.

But somehow none of them succeeded particularly well. Now, we can ascribe all the success to Elon Musk's charm, but it still doesn't explain that despite the seeming interest in multiple places, especially deep pocketed ones like the military, this field didn't get much boost.

If it wasn't all that hard, and we did care about the problem to some extent, then my conclusion is that these sociological examinations perhaps miss the broader technological point. It wasn't that we didn't want to, it was that the underlying technology to make this come about simply didn't exist. Three examples:

Materials

The materials used in Space X rocketry are oftentimes state of the art, with their reliability bolstered through repeated tests rather than relying on history. For instance:

For the Dragon’s heat shield, the company chose a material called PICA (phenolic impregnated carbon ablator), first developed for NASA’s Stardust comet-sample-return spacecraft. Rejecting the prices they were getting from the manufacturer, they took advantage of help from NASA’s Ames Research Center to make it themselves. According to Mueller, SpaceX’s material, called PICA-X, is 10 times less expensive than the original, “and the stuff we made actually was better.”

Without the availability of these types of materials, the chances of iterating on designs and trying new paths to space wouldn't be feasible. It's a contingent fact of history that we had to wait for some of these to become available.

Manufacturing

SpaceX also use 3D printing to great effect. They use direct metal laser sintering, a type of additive manufacturing, to lay down thin layers of metal powder in a heated chamber, having a laser trace out the 2D cross section of the part you want, then using the laser to melt the metal powder where it's been laid down, and then adding the next layer on top. So on and on.

This is used, for example, to create the engine chamber for the escape pod. The metal used is Inconel, discovered in the 1940s, and known to be difficult to shape and machine with the traditional techniques. The method was also used to build oxidiser valves for the original engine body for Falcon 9. This wasn't an isolated incident, they had to design new machines to create parts that didn't exist. (Friction stir welding was discovered in Dec 1991)

SpaceX had to design a machine that could friction stir weld aluminum-lithium alloy for the airframe of the Falcon 9 because such a machine did not exist

This technique would not have been possible to deploy at scale were Space X started in the 1990s. The computational power didn't exist yet, and neither did the knowledge. If, as Musk wanted, they needed to create reusable rockets, then they would need components that didn't exist yet, and the only way to build that future was to control the whole supply chain.

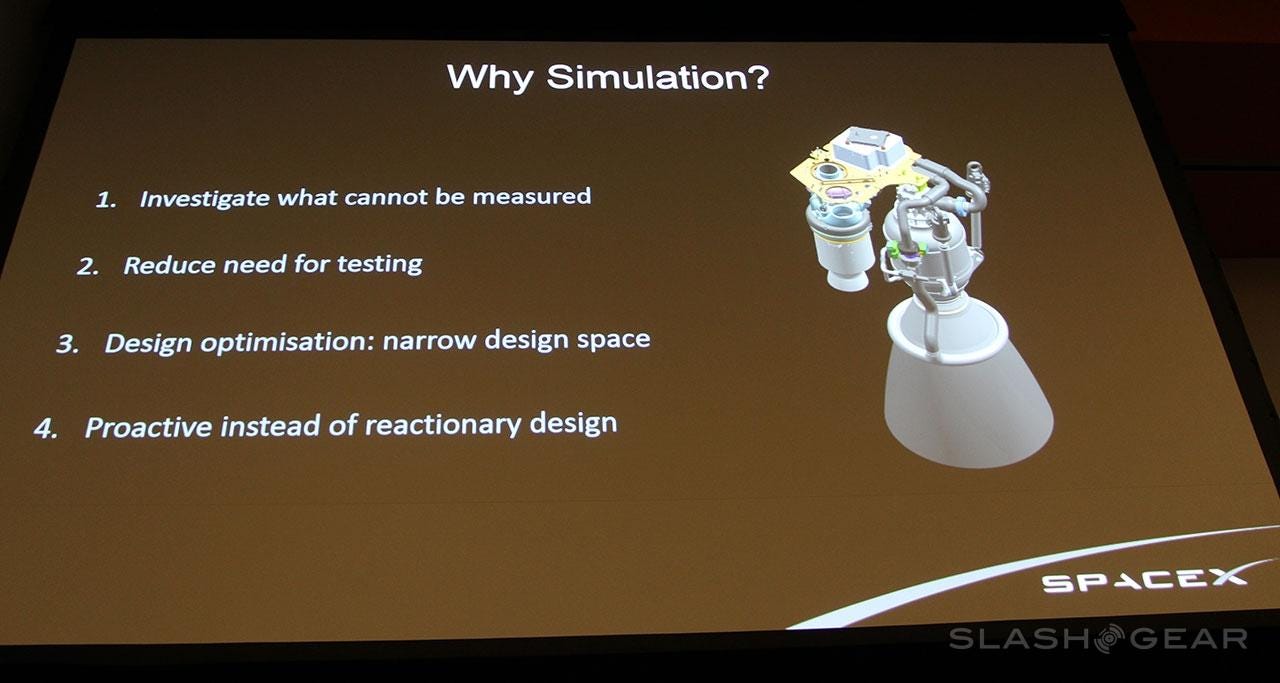

Simulations

The first proper flight of the space shuttle was crewed, and before they only really had atmospheric testing of the orbital. But now, Space X has detailed simulations of almost every variable involved in the design and operation of its rockets. There's simulation work to not only figure out the right composite materials to use for manufacturing, but also for testing and perfecting the design.

Then there's real world testing, including in a wind tunnel, but that's for validation and rejiggering the assumptions since fluid dynamics is a fickle beast.

From a 2015 talk given by SpaceX Director of Research Adam Lichtl and SpaceX Lead Software Engineer Stephen Jones:

In these cases, SpaceX had to wait for the rest of the technology world to catch up. Computers wouldn't be good enough to run these simulations until well into the 2000s. Material science wouldn't catch up until 1990s and even later to be used in production. Manufacturing techniques through 3D printing were barely useful for extremely expensive toys in the 80s, and took until the mid-1990s to become usable, when folks from MIT, Stanford and Carnegie Mellon figured out techniques including microcasting.

These technologies became substantially cheaper and way more powerful in those couple decades, often by incredible orders of magnitude. For instance, the average cost of a 3D printer went from $300k in 1984 (c.$650k w' inflation) to c.$30k in 2014. That's a 21x decline in price alone! Once you add functionality, in most cases you couldn't even do what you wanted in 1984, whatever the cost. You couldn't 3D print a five storey residential apartment, or a fully functioning robot or a working rocket engine.

Not only does the market itself grow, it co-evolves with the materials market, because finding new materials it can use to print is critical to the growth of the industry. Polymers, for instance, are the most widely used. But there's an increased demand for high performance thermoplastics including carbon reinforced composites, not to mention other ones like ceramics and metals. And the prices of these materials also are coming down because of increased usage. A classic positive feedback loop.

The reason Space X exists today is at least partially because it can do things today that it couldn't have done 2 or 3 decades ago.

III

Let's try another way to play corporate time machine. Suppose you were present in Silicon Valley in the 1980s. The semiconductor industry was booming. The PC revolution was starting. Software was slowly becoming a 'thing'. Bill Gates was being acting his age and being suitably capricious. Moore's Law seemed to hold true, now and seemingly forever.

And then the cold water gets poured by none other than Robert Solow stating in 1987:

the computer age was everywhere except for the productivity statistics

And maybe you wanted to say, well hold on for a second! We've just started going here. Ten years ago we were all either plugging away at analog machines or working on mainframes with punchcards like kids at an arcade, and you're already complaining? The ingratitude!

Maybe you have another conversation with the grumpy Mr. Solow a few years later to say, isn't this amazing? Technology is still booming, Moore's Law is starting to look more and more like a real law, and we even have the internet! Not only have we miniaturised compute power, we have connected those nodes with each other. You could even scare the occasional computer student at Carnegie Mellon making them believe in thirsty ghosts.

At that point we start to see from an NBER paper:

unmeasured investments in intangible organizational capital—associated with the role of information and communications technology (ICT) as a ‘general purpose technology’—can explain the divergent U.S. and U.K. TFP performance after 1995.

Again, this plateaus within a few years. and starts the pundits wondering if Solow's paradox is back.

And now, we have used the ever increasing compute power and the internet to help make things happen that weren't possible before.

Even something as trivial as Clubhouse required the development of ubiquitous smartphone penetration, a non-fragmented Operating System base to work with, back end audio infrastructure providers like Agora or Twilio, who themselves rely on infrastructure like AWS, not to mention the absolute explosion in areas like UI creation and coding libraries and tools that are now available. Building Clubhouse in the early 2000s would have been nearly impossible. Now it's trivial.

Space X isn't all that different, except that it still isn't trivial. Like any large capex heavy industry that is highly regulated and is incredibly sensitive to failure, it's not an easy one to get behind. But it still needs the underlying technology to catch up.

That's why the adoration for SpaceX falls into what I call an isolated narrative of progress. The narrative treats its very existence as a de novo entity in almost miraculous terms. But there are historic contingencies that matter here.

However much we want to think about the growth of an industry or progress within a science as a matter of our willpower and intellect, it's a compounding process. There are towering minds that focused on the smallest problems to solve them, whether it's the discovery of the world wide web or the programming languages we use or even Linux, which helps create the base atop which we can create new structures.

So when we ask if SpaceX could've been built in the 1980s or 1990s we're essentially asking whether SpaceX could have internalised the entire progress in a few different industries in the 1980s or 1990s. The progress rate of computational power was much more rapid than the progress rate for material science. In many cases the material science had to wait to use the computation power generated to reignite its growth (see simulations to test and create new materials). New manufacturing processes had to wait for both material science to catch up and for computers to have sufficient hardware power and software capable to controlling it. That's what contingent evolution here means.

We started by looking at this particular industry from a Great Stagnation lens. But stagnation implies stasis. Which is not the case here. It's more like a pregnant pause when the engines are getting revved up. In the process of evolution it might feel for a long while that nothing much is changing, but once the cumulative changes in individual genepools start adding up, we can see quick transitions.

Stephen Gould called it the punctuated equilibrium theory - where we had periods of seeming equilibrium punctuated by periods of rapid speciation and growth. What we see in the technology world is similar, periods of seeming stagnation, which are actually not artefacts of stasis but rather points where we are accumulating multiple new tools and technologies that enable us to take a giant step forward.

While everything you say is true, I'm not sure those are the main factors. There were two other important factors that weren't technical. First, the US was obsessed with the USSR and the cold war, so most of the money and technology went into weapons. Even the moon race was based on the cold war and not on exploration. For evidence, look at the new moon race now that the new boogie man China is going to the moon. When the USSR collapsed in 1991 there was an opportunity to refocus. The second reason is cost-plus contracts and cost maximization in the industry. I worked for a major aerospace company in the 1980's, and the whole industry was pervaded by this. They had no interest whatsoever in lowering costs, because that lowered their contract amount the next year! So for example, if a company had a contact to make a widget for $100 million, and they only spent $90 million, then the following year their contract would be reduced. With cost-plus whatever they spent was the base amount plus an amount added to that. So why on earth would they want to reduce costs? They wanted to maximize costs within the limits of the contract. Third, according to a talk by Robert Zubrin several other billionaires tried to build rockets and all failed. Compare Bezos Blue Origin with SpaceX. That's because Bezos is a glorified salesman and knows nothing about engineering, and Musk is a physicist and engineer. And as you said, space is hard.

Regarding Clubhouse. The argument is wrong. Skype was released in 2003. Cellphone conferencing was available in the 1990s. Multi-user phone connections were a technical possibility since the first phone networks were created. It would have been trivial to create Clubhouse on a mobile or on a stationery phone at any period in time (or on a Minitel in 1980s). A Clubhouse on a PC could be created (with avatars and a good UI) in late 1990s. In fact, the Mother of all Demos (1968) featured simultaneous video/audio communication overlayed on the computer interface. Various telepresence technologies were in use in ARC in the 1970s. Building Clubhouse was trivial at any period in time. The only difference now is the availability of cheap venture capital to fund arbitrarily frivolous projects as long as the potential for exponential growth is there. Trust me, I am a UI historian and an IT architect.

I don't know whether something similar can be said about SpaceX, but my guess would be that technically it is possible. The Lunar Lander did something similar to what Falcon rockets do. There doesn't seem to be any radical differences between a Soyuz and a Falcon. Yes, a Falcon is engineered using modern tech. But that doen't allow one to argue that you could not land boosters in the 1960s (even automatically).